ecosystem communication

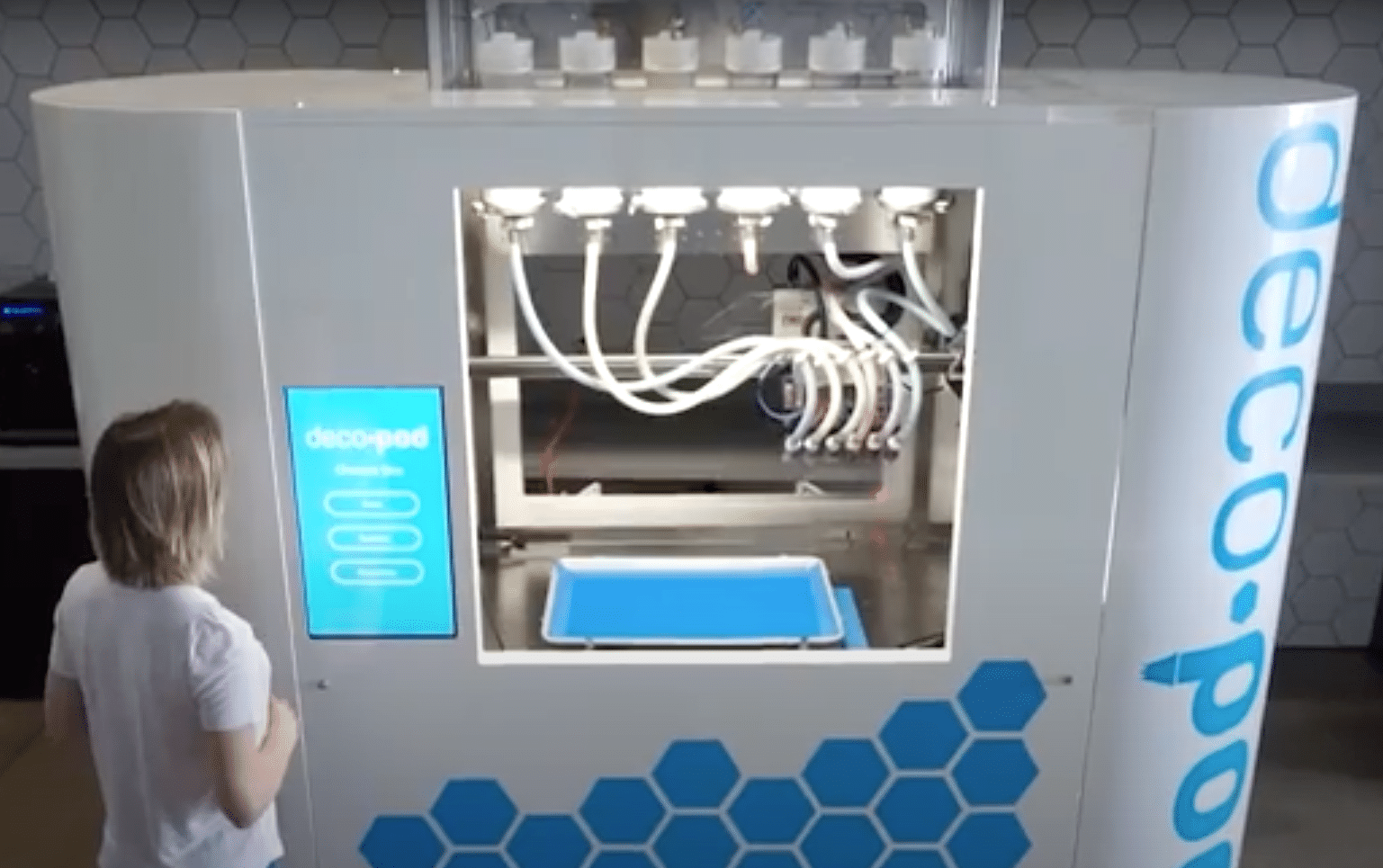

A start-up manufacturing firm which has designed specialized and sophisticated 3D printing hardware from scratch, BeeHex has a need to ensure crystal clear communication of product information among its internal team, out to its sub-component suppliers and manufacturing partners, and onward to its customers in the commercial food sector.

Co-Founder and COO Benjamin Feltner explains that, with engineering resource at a premium as products are developed and refined, any solution which can generate time savings and efficiencies is prized by his team.

Using screen shots taken from Solidworks to create visual documentation in Microsoft Office applications was restrictive and time-consuming so BeeHex turned to Canvas X Pro.

“It enables us to provide absolute clarity to all of our stakeholders. We need to create drawings for our manuals, for our customers, and for our manufacturing processes. We were using screenshots taken from Solidworks but it just wasn’t good enough – both in terms of what we could communicate and the process itself. Instead of spending our time managing this workflow, we wanted a tool that was suited to the job.”

quicker access to essential information

BeeHex is growing fast and with every new contract comes a custom requirement or modification to the firm’s core production model. This creates fresh requirements in terms of technical documentation.

A lightweight, high-value and intuitive desktop software which offers a significant cost advantage over other packages, X Pro allows BeeHex engineers to import 3D CAD models directly from Solidworks and use them to create visualizations for technical documentation aimed at a broad audience.

And Canvas X Pro can import files from all leading 3D CAD packages, giving market leading versatility and value.

The ability to manipulate 3D models to capture whatever view is required – to explode, rotate, ghost, and hide individual parts – and then add callouts, annotations, and tables using BOM data makes Canvas X Pro a perfect addition to the design and manufacturing process.

It provides a single application in which BeeHex engineers are able to manage all of their technical documentation needs.

communication that saves time and improves clarity

“We need to show everyone exactly what is going on with our solution and that requires visualization. If you don’t have an easy way of making this happen then you waste so much time trying to explain it in other ways. Canvas X Pro is really an important communication tool and it helps us provide that clarity.”

learn more about canvas

Canvas is chosen by leading manufacturing brands from all verticals because it has been developed specifically to cater to precision technical illustration use cases.

.png)